1/05

10-150

DocuColor 12/DCCS50

Mailbox/Sorter PWBAs, Print Transport through the

Reissue

Principles of Operation

Mailbox/Sorter PWBAs

The Mailbox/Sorter has two PWBAs:

•The

Mailbox/Sorter Control PWBA, shown in Figure 2, monitors paper path sensors, inter-

lock switches, bin full switches, OCT full switch and

OCT present and home position sta-

tus.

•The

Decurler PWBA, shown in Figure 3, monitors the paper path through the Decurler

and controls the decurling function and communicates with the Mailbox/Sorter Control

PWBA.

The Mailbox/Sorter Control PWBA includes four (4) LEDs. The IOT CPU PWBA has LEDs that

li

ght t

o indicate active communication between the two PWBAs.

A self-test is performed on the Mailbox/Sorter Control PWBA during power on.

Print Transport through the Mailbox/Sorter

The Mailbox/Sorter contains three (3) motors. Table 1 shows the Mailbox/Sorter motor func-

tions.

Decurler control

The Decurler neurtralizes paper curl that results from the Xerographic process. The basic con-

cept of decurling is to force a smaller diameter met

al roll with a hard surface into the much

softer foam surface of a larger diameter roll. This creates a valley in the larger roll, and the print

is forced into this valley in the opposite direction of its natural curl. Prints curl toward the side

having fused toner.

Paper curl and the decurling proces

s is

dependent upon these variables:

• Paper weight and type

• Single or two sided copies

• Black-and-white or Color copies

• Pixel density

•Humidity

To address the different amount and directions of paper curl, the Decurler Motor operates at

dif

ferent

speeds and one of the two Decurling Rollers cam up or down by different distances to

decurl the paper.

The Decurler Motor has the following adjustable parameters:

• The distance by which the harder roll is forced into the surface of the softer roll, called the

Nip Shif

t

• The speed at which the paper travels through the decurler

• Which decurler (upper or lower) is active

Refer to Figure 1 and

Table 2 for details of the components for this function.

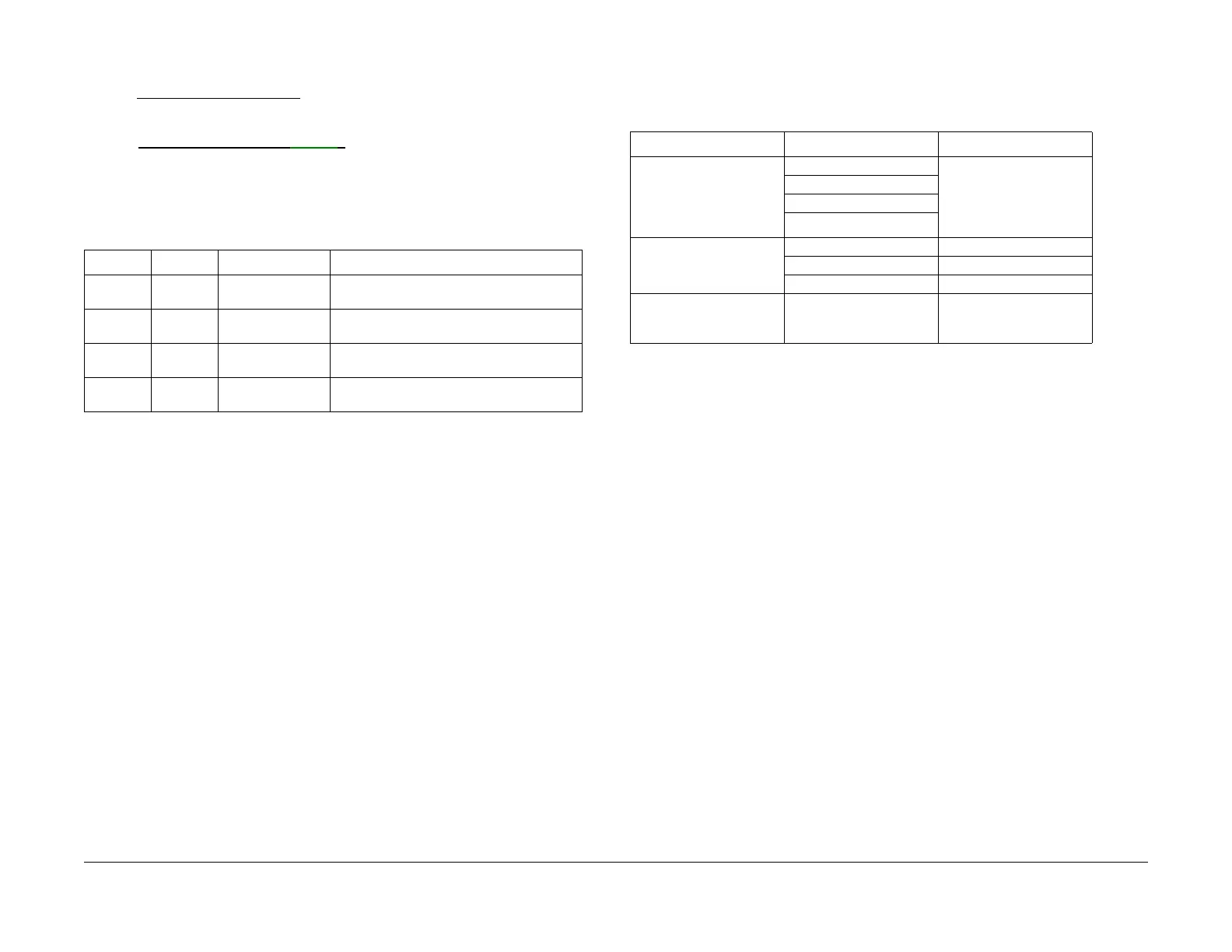

Table 1 Mailbox/Sorter Control PWBA LEDs

LED Color Signal Comment

CR1 Vcc Lit indicates that digital logic power is avail-

able

CR2 RxD Flickering indicates command data being

rec

eived f

rom IOT CPU PWBA

CR3 Reset Lit indicates that PWBA microcontroller is

being res

et by IOT CPU PWBA

CR4 /Lock Lit indicates that Mailbox/Sorter Assembly

Motor is

locked.

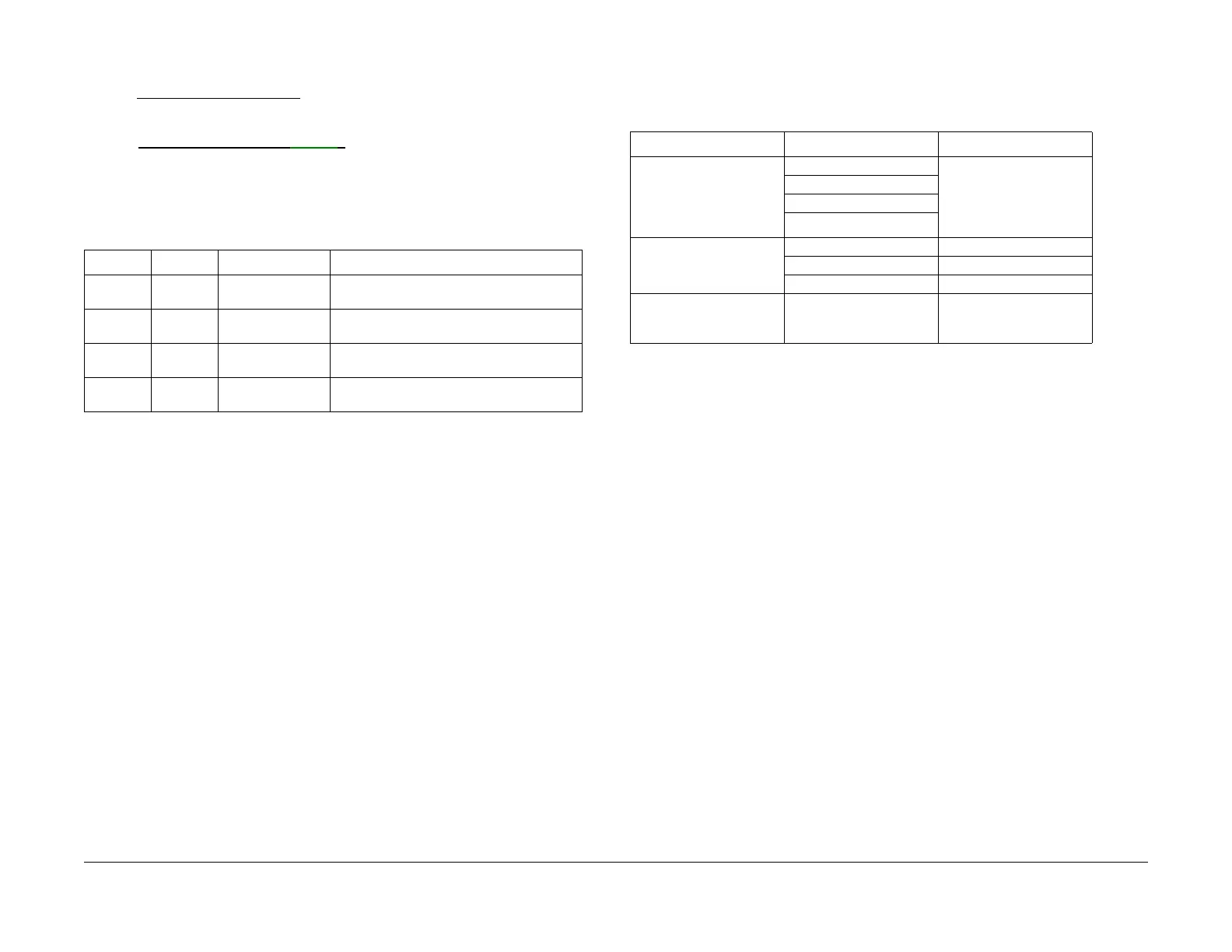

Table 1 Mailbox/Sorter Motors and Functions

Motors Drives: Transport Speed

Decurler Motor

(+24 VDC Stepper)

Decurler In Roll 350, 220, 130, 60 mm/sec.

1st Decurler Roll

2nd Decurler Roll

Decurler Exit Roll

Sorter Motor

(+24 VDC Stepper)

Sorter Entrance Roll

1-10 Vertical Bin Rolls

Sorter Exit Roll

OCT Motor

(+24 VDC Bi-directional)

(optional with printer)

Offset Catch Tray

manuals4you.commanuals4you.com

Loading...

Loading...