1/05

10-142

DocuColor 12/DCCS50

Functional Description of Fuser Subassemblies

Reissue

Principles of Operation

The low oil signal from the sensor also starts a software timer in the machine. The timer will

allow approximately 2000 additional copies to be run during this “warning period” before the

machine will shut down. During this warning period, if the front door interlock is opened, the

“Replace Fuser Oil Cartridge Soon” message will disappear from the UI for 10 minutes. If after

the 10 minutes, the Oil Sensor still detects a low oil condition, the message will be displayed

again on the UI.

When the software timer expires (approximately 2000 copies), a “Replace Fuser Oil Cartridge”

mes

sage

is displayed on the UI. When this condition occurs, the machine shuts down. Install-

ing a new Oil Cartridge will enable the machine to run jobs again.

Oil usage rates vary, depending upon the types of images and media being run. Under normal

condit

io

ns, an Oil Cartridge should last approximately 25-40K copies/prints. Oil rates can be

much higher when the oil metering system is in need of service.

Web Cleaning of the Heat Roll

The Web Assembly is a Customer Replaceable Unit (CRU). The Web material is a low fiber,

paper-like material that removes toner and paper particles which may adhere to the Heat Roll

during the fusing process. A metal Cleaning Roller is also used to remove toner residue from

the Heat Roll. The Cleaning Roller is driven by direct contact with the Heat Roll.

The Web material is held in constant contact with both the Heat Roll and the Cleaning Roll.

F

urt

hermore, the Cleaning Roll is held in constant contact with the Heat Roller by two foam-

covered Web Pressure Rollers. The Web Pressure Roller holding Web against the Heat Roller

is spring loaded. The Web Pressure Roller holding the Web against the Cleaning Roll and the

Cleaning Roller against the Heat Roll is held by gravity.

The Web material moves in the opposite direction as the surface of the Heat Roller as it travels

f

ro

m a Supply Roll to a Take-up Roll. The IOT Control and Status PWBAs can approximately

determine how much of the Web Material has been used. Through a hard stop circuit, the

machine is shut down when the Web material runs out.

There are three physical stages to metering the Web usage; New, In Use, and Empty. There is

also a non-phys

ic

al stage where the machine software determines a “Web Low” warning state

on the UI. These stages are detailed below.

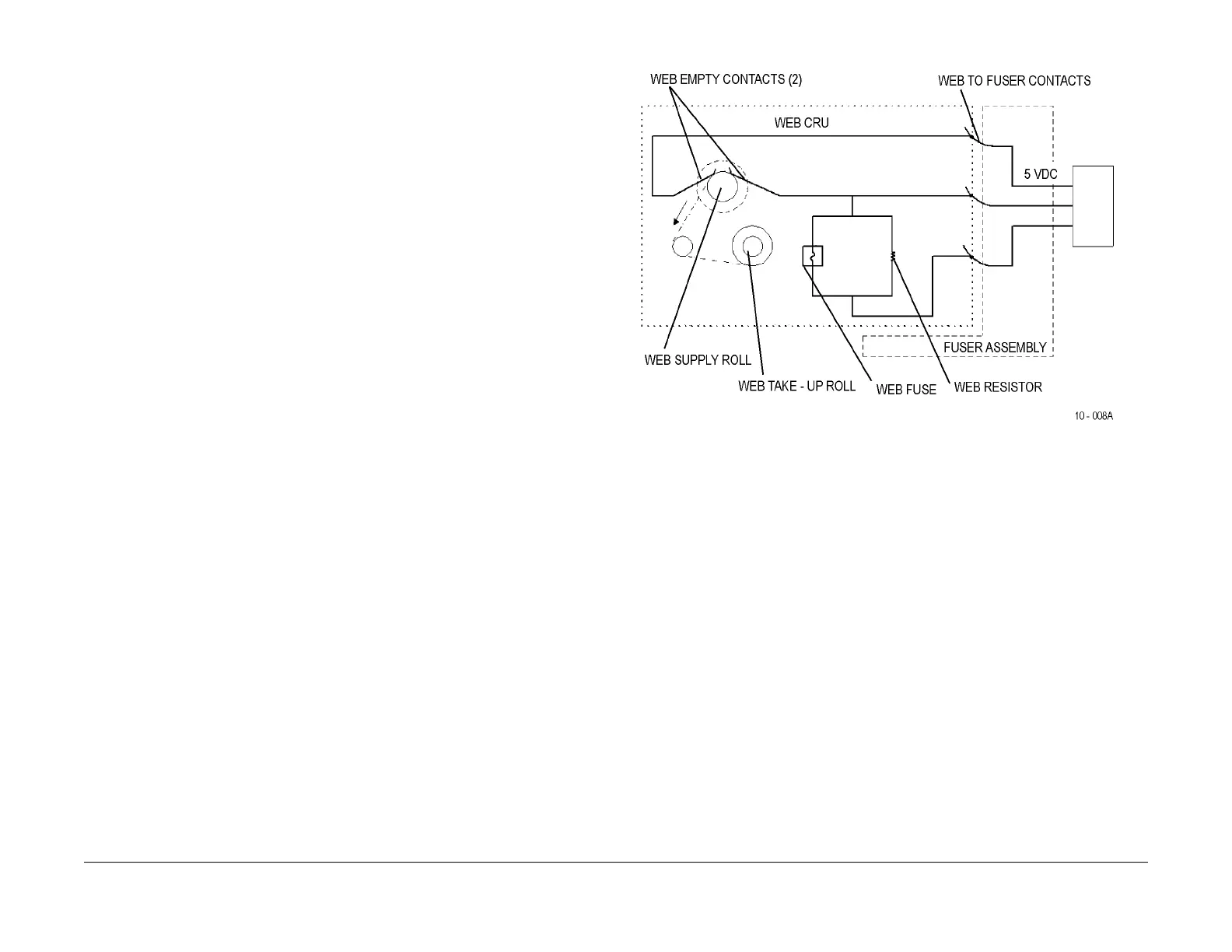

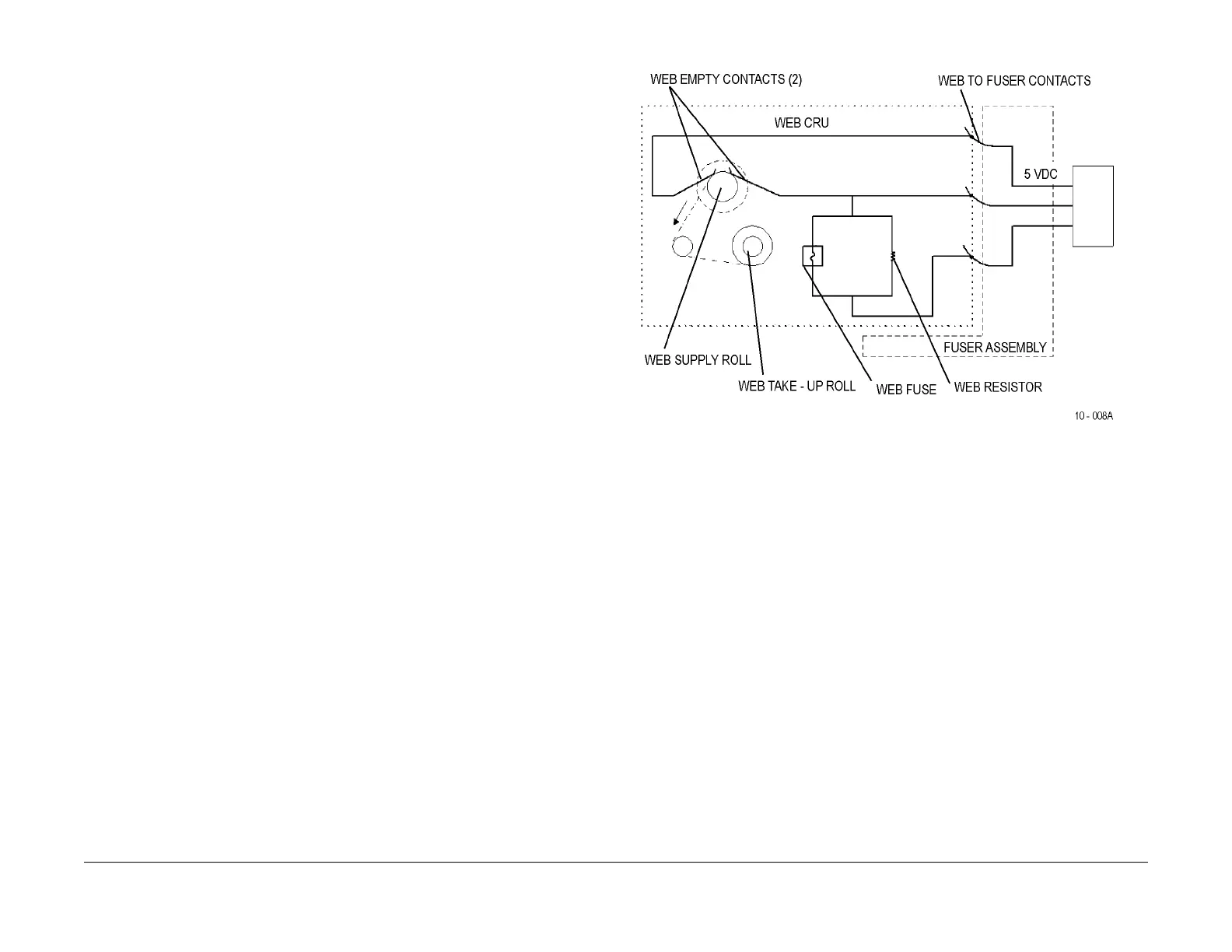

First, as shown in Figu

re 5, the Web Assembly has an electrical circuit that contains a fuse.

When a new Web Assembly is installed, the fuse is immediately opened. This transition indi-

cates to the Control Logic that a new Web Assembly has been installed. The IOT Control

PW

BA

resets to “0” a variable indicating how many copies have occurred for this Web Assem-

bly. As copies are made, this variable is incriminated.

Figure 5 Web Assembly circuit

The IOT Control and Drive PWBAs advances the Web Material

by activating a dedicated Web

Motor. This causes Web Material to pass from the Web Supply Roll to the Web Take-up Roll.

The interval that the motor is activated can vary between one and four seconds. How long the

motor is activated depends on two factors.

• The motor is on for twice as long for color jobs than B & W jobs.

• The period that the motor is on decrease with the amount of Web Material that has been

used

in the c

urrent Web Assembly

As more material is used, the effective diameter of the Take-up Roll core increases. Therefore,

the

Web Material is transferred between rolls more rapidly. The IOT Control PWBA uses a copy

count variable to estimate the amount of Web material that has been used. This determines the

amount of Web Motor activation time for each copy, based upon a rough estimate of the Take-

up Roll core diameter.

Once the total Web Motor ON time reaches 1458 m

inut

es (approximately 40,000 copies), a

“Replace Cleaning Web Soon” message is displayed on the UI. This message will remain dis-

played for approximately 3,000 - 5,000 copies until t

he Web A

ssembly circuit detects the Web

Supply Roll is empty. When empty, two metal contacts touch the metal Supply Roll core and

completes a circuit. When this occurs, the machine becomes disabled and a “Replace Clean-

ing Web” message is displayed on the UI. T

his condit

ion ends when a new Cleaning Web

Assembly is installed.

manuals4you.commanuals4you.com

Loading...

Loading...