1/05

4-215

DocuColor 12/DCCS50

ADJ 12.1.1

Repairs and Adjustments

Reissue

ADJ 12.1.1 DADF Side Registration

Parts List on PL 12.1

Purpose

To ensure that the document is set into the correct position on the Platen (front-to-rear drum

axis direction).

Check

NOTE: Before running this function, the side registration in the Platen mode must be properly

adjusted (ADJ 9.1.15).

1. Place the test pattern (82E8220) on the Platen so that there is no gap between the test

pat

tern and the Registration Guide at the rear.

2. Copy the test pattern in the following copy mode:

a. Copy mode: Black

b. Paper tray: 11” x 17” or A3

c. Magnification: 100

d. Number of copies: 2

3. Number the ejected document pages as "1" and "2" in t

he order that they are ejected.

4. Measure the distance between the paper side edge of the second document (2) and the

tar

get line. Assume this distance is A (Figure 1).

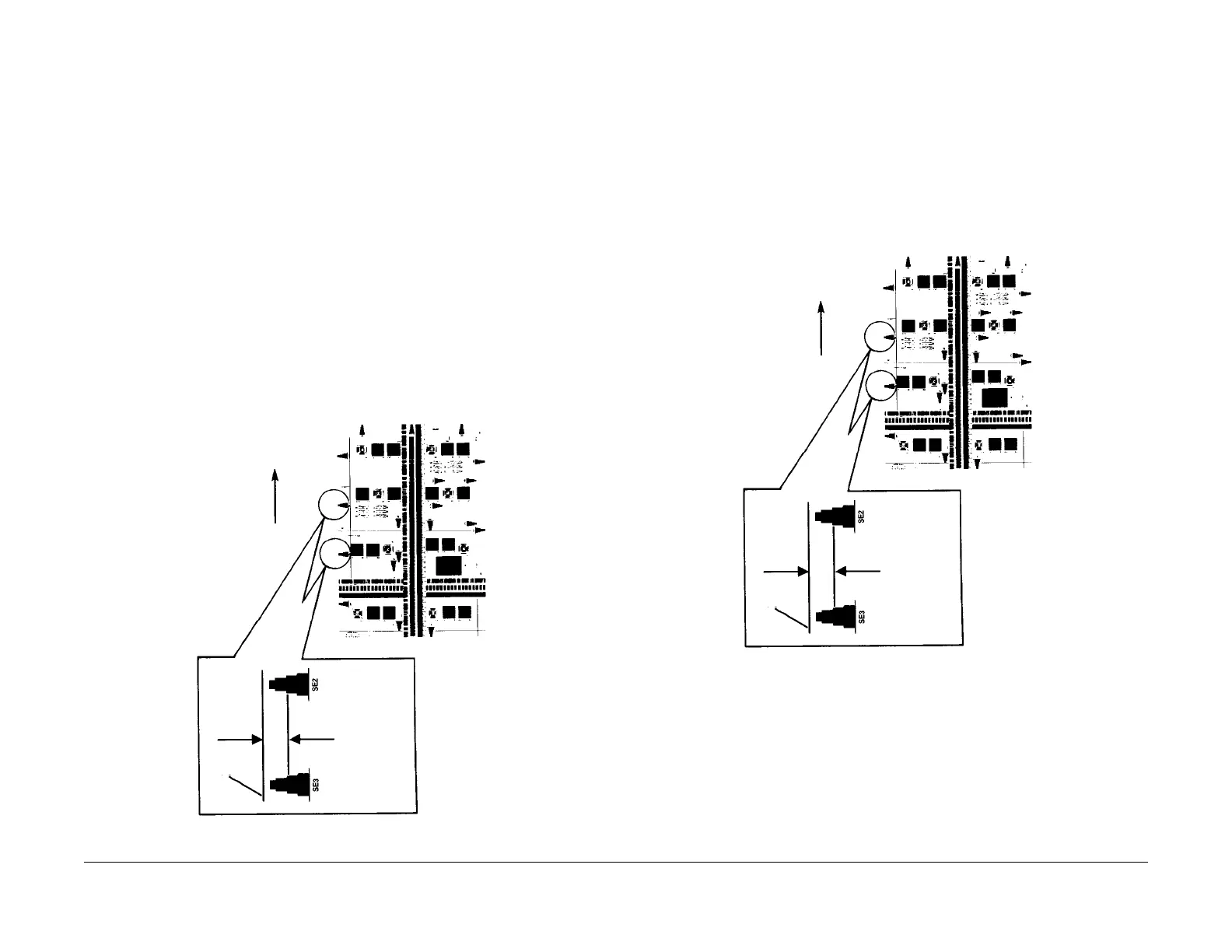

Figure 1 Checking the Side Registration A

5. Check that the value A is 10.0mm ± 0.

6mm.

If the value is not within the range, perform

Side/Lead Edge Registration(ADJ 9.1.10), then return to this procedure.

6. Place the two document pages in the DADF. (The number "1" page is on top, and the bot-

tom edge is fed in first.)

7. Set the following copy mode and make a copy.

a. Copy mode: Black

b. Paper tray: 11” x 17” or A3

c. Magnification: 100

d. Number of copies: 1

8. Using the number “2” copy, measure the distance bet

ween the paper side edge and the

target line. Assume this distance is B (Figure 2).

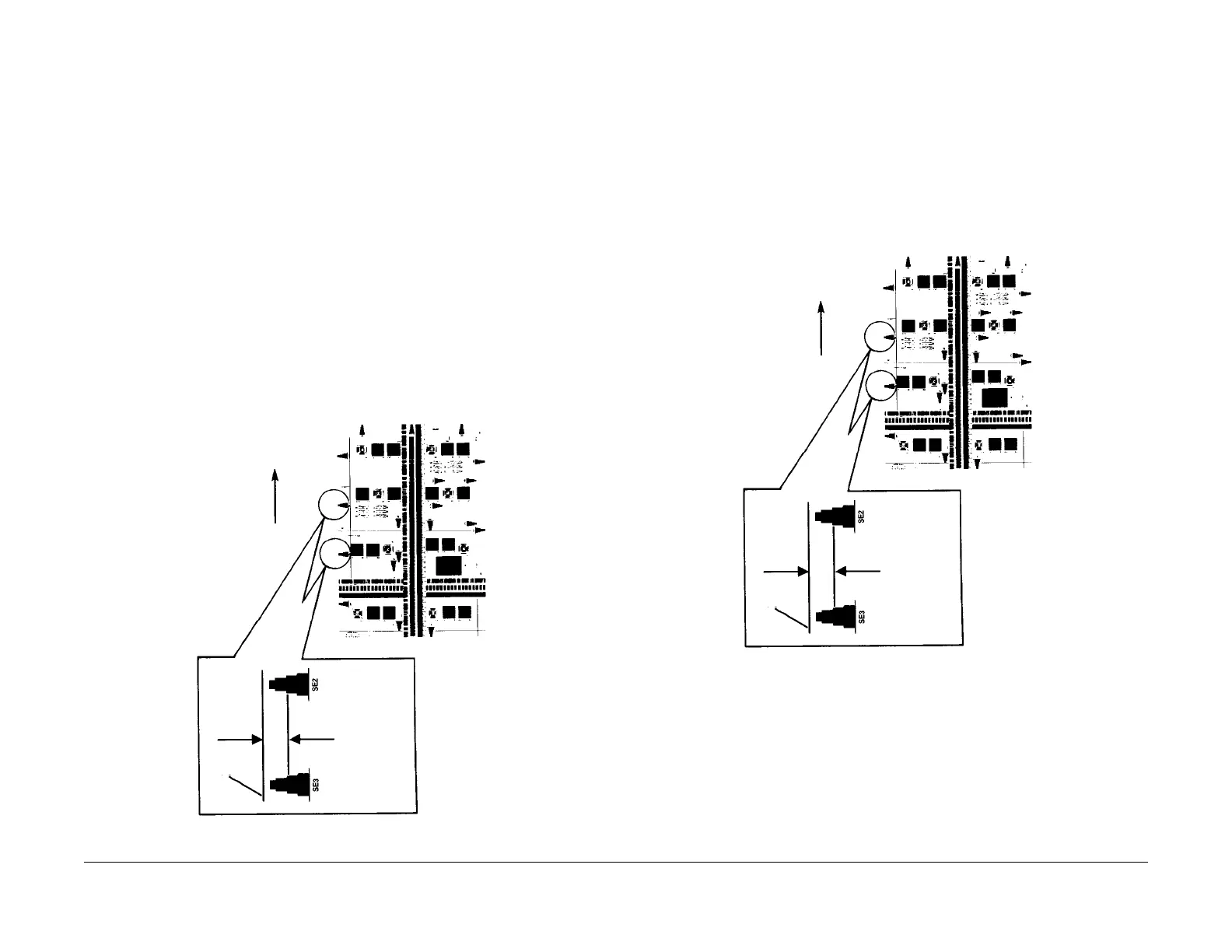

Figure 2 Checking the Side Registration B

9. Check if B - A is 0 ± 1mm.

Adjustment

NOTE: You can adjust the side registration of the DADF simplex or duplex.

1. Enter the dC131 NVM Read/

Write[715-028] (DADF IPS Offset)

2. If B in step 8 of the check is,

a. 10.6mm or more: Increase the NVM value;

b. 9.4mm or less: Decrease the NVM value.

(each NVM step=1mm)

A

Edge of

Copy

PAPER

FEED

DIRECTION

PAPER

FEED

DIRECTION

Edge of

Copy

B

Loading...

Loading...