1/05

10-121

DocuColor 12/DCCS50

Development

Principles of Operation

Reissue

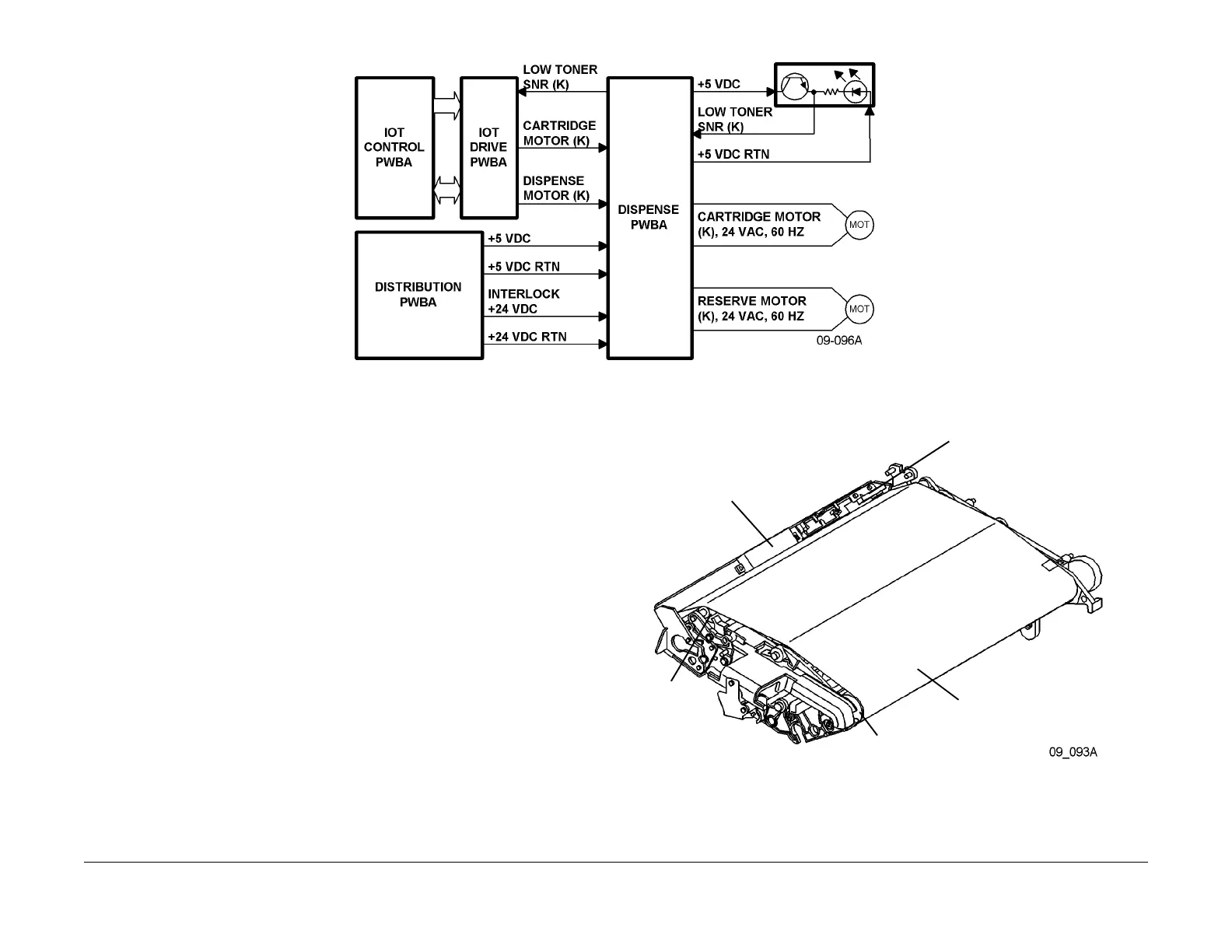

Figure 8 Toner Supply Control Simplified Block Diagram (Black)

ADC (Automatic Density Control)

The ADC Sensor is a Polarized Color Densitometer (PcDM) consisting of a Light Emitting

Diode (LED), a phototransistor and a polarizing filter. The ADC Sensor is located in the IBT

Assembly. This sensor reads the reflected light from a toner patch placed on the IBT Belt. This

reflective reading is used by Process Controls to determine the density level of the image

which will then determine the required running times for toner dispensing.

The current through the phototransistor is proportional to the amount of light reflected from the

developed p

at

ch. The current is converted to a voltage level on the ADC Sensor PWB and that

voltage signal is sent as two analog signals through IOT Drive PWB to the IOT CPU PWBA

where it is used for process control functionality. The ADC Sensor and ADC Sensor PWB are

part of the ADC Sensor Assembly. Refer to Figure 10 for a block diagram of the ADC Sensor

control.

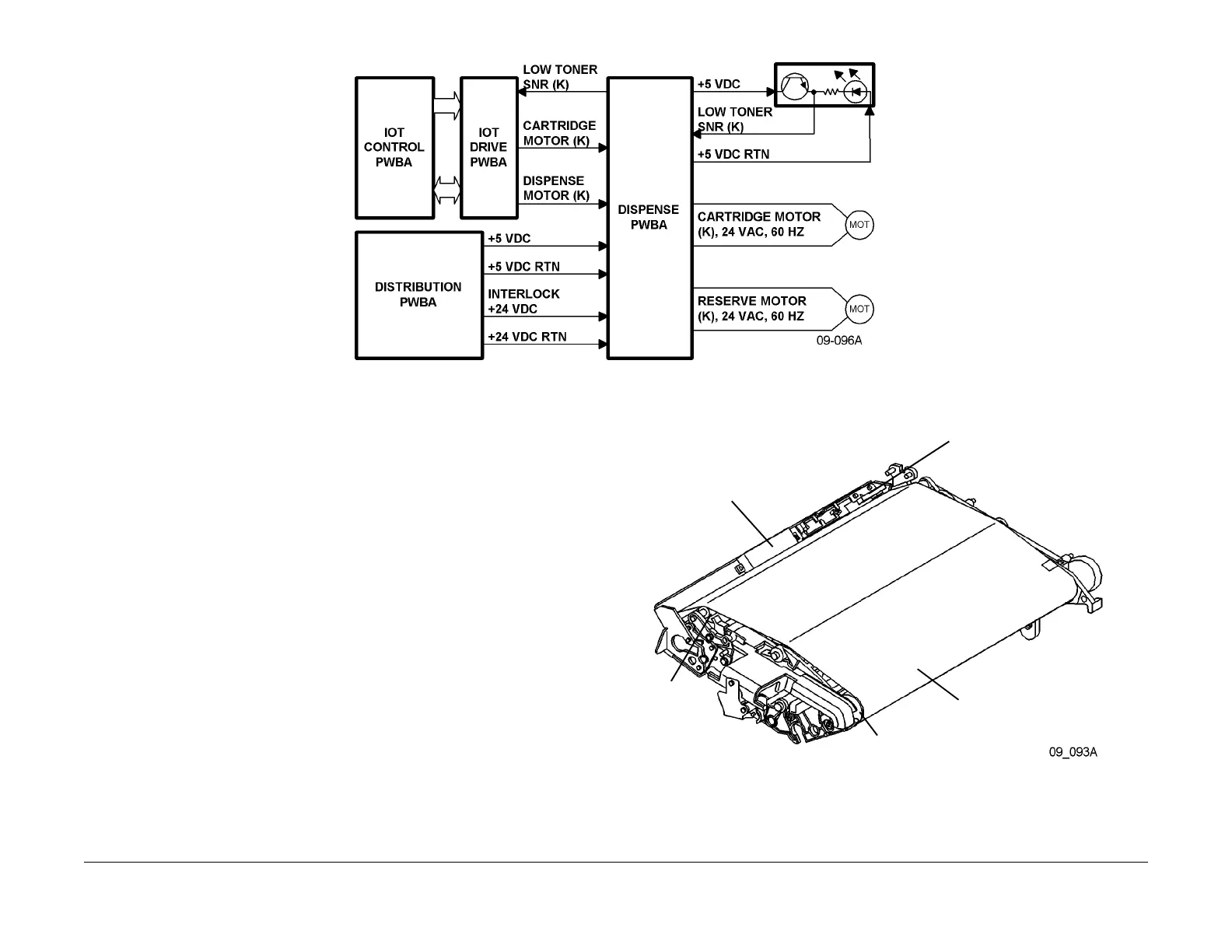

Figure 9 IBT and Selected Subassemblies Locations

ADC patches are made and read:

ADC SENSOR

TR0 SENSOR

IBT BELT

DRIVE ROLL (INSIDE

BELT)

STEERING

ROLL

(INSIDE

BELT)

Loading...

Loading...