1/05

3-42

DocuColor 12/DCCS50

IQ 46 Black Bead Carryout RAP

Reissue

Image Quality

IQ 46 Black Bead Carryout RAP

This RAP is used when the copy is experiencing bead carryout (BCO) for the color black. This

defect looks like mottle and is most noticeable in the high density areas. BCO is caused by low

toner concentration.

NOTE: Only the effect the carrier beads have on the image of the output copy/print are visible.

T

he beads

are physically trapped by the fuser web and therefore will not be observed on the

copy/print.

Initial Actions

This RAP assumes IOT s/w version 6.00.2 or higher is installed. If not, go to IQ 19 Bead Carry-

out RAP to begin troubleshooting.

Ensu

re that the paper presently being used is fresh 24 lb. Xerox COLOR Xpressions (NASG),

or 90 GS

M Colortech + (ESG) paper or paper which is included in the customer’s Materials

Usage Guide and Recommended Paper List. Run test copies. If the copies reproduced still

have Bead Carryout, continue with this RAP.

Procedure

NOTE: Ensure that 8 1/2 X 11” LEF paper is installed in Tray 2 before continuing.

Enter the diagnostic mode from the UI and select MAX Setup. Select TRC Set UP/Toner Con-

centration Adjustment. Select TRC Control (dC922). Make a ProCon test pattern by pressing

the S

tart button. Examine the copy for mottle-like or non-uniform (spotty) density in the high-

density patches. One of these defects is present in the 100% patch (top row) in black.

YN

Go to I

Q 2 Defect Listing and choose

one or more of the following defects to continue

troubleshooting: mottle, high image density, deletions, or spots.

Select Close three times to take you back to the main menu. Select NVM Read/Write. NVM

locati

ons 773-021 through 773-028 are set to “1”.

YN

Select MAX Setup. Select and run ADC AGC Setup (dC934) and VH/VM Setup (dC933)

in M

ax

Setup (dC929) and investigate any system failure that is declared.

NVM 773-004 is set to “1”;

YN

Set NVM to “1”.

The value in NVM location 773-121 is between 5 and 95 (this number represents the per-

centage of room humidity).

YN

Replace the Humidity Sensor (PL

7.

1).

Refer to Tabl

e 1 to ensure that all the NVM settings indicated are correct. If any NVM value

needs to be changed, replace the developer material (REP 6.6.2). If all NVM values are correct

but it has been less than 2,000 copies since the IOT s/w 6.00.2 was installed, replace the

developer material (REP 6.6.2).

If the problem continues, perform the following correct

ive act

ion steps in order until the problem

is resolved.

• If the density is still light, check the Toner dispense s

ystem f

or any blockage or obstruction

that could limit the amount of Toner reaching the Developer Housing.

• Enter dC922 (TRC Control) from dC929 (Max Setup). Manually tone up black by setting

the

Tone Interval to 12. If the problem is resolved, refer to Table 1 and set NVM 775-664

to 70 and NVM 775-669 to 65.

• Replace the Developer Bias Brush, if damaged (REP

6.1.

4)

• Replace the Developer Housing, if damaged (PL 6.6).

•G

o to IQ 37

Developer Bias HVPS RAP.

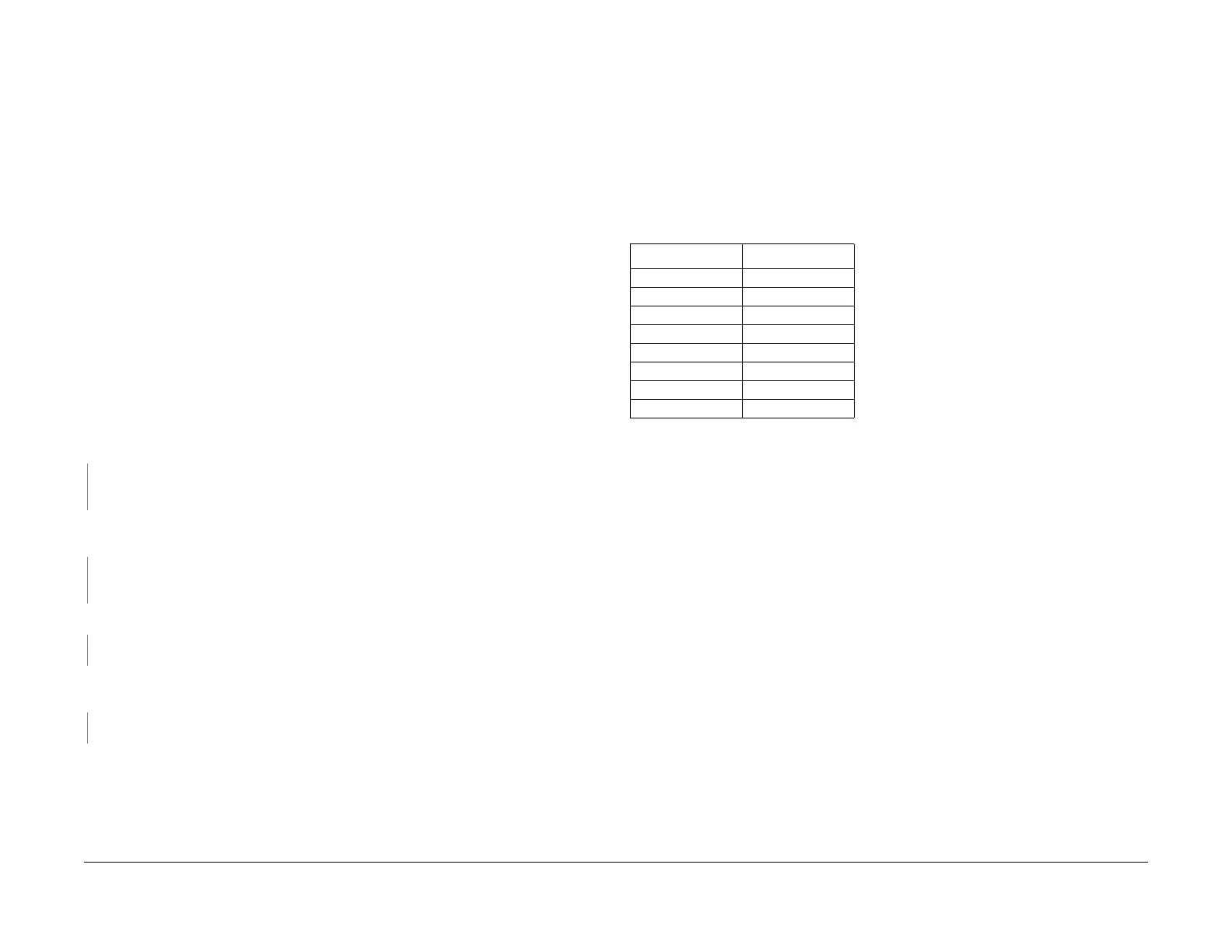

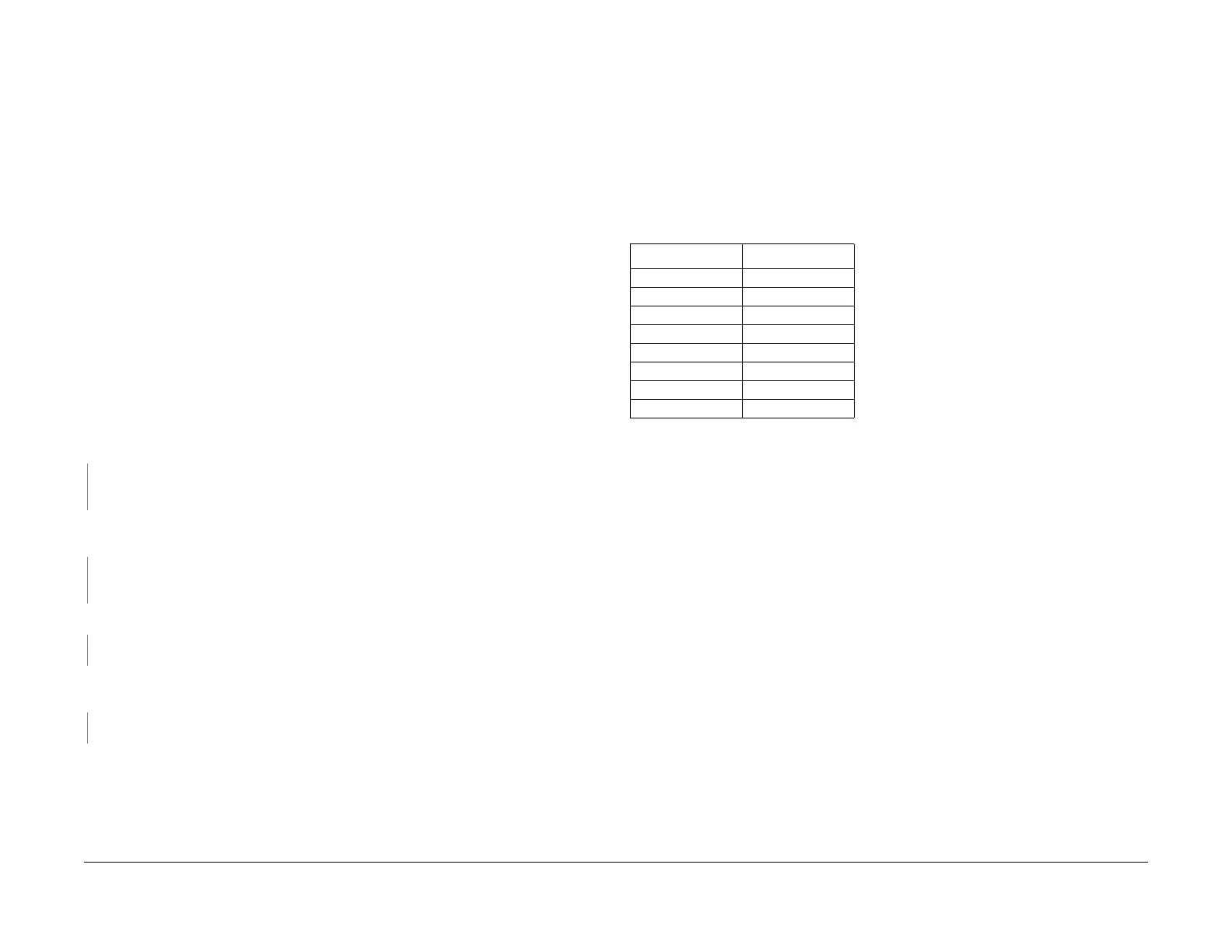

Table 1 NVM Settings

NVM Location NVM Value

773-223 200

773-269 160

775-681 1

775-664 65

775-669 60

775-673 100

775-914 100

775-924 100

manuals4you.commanuals4you.com

Loading...

Loading...