1/05

10-128

DocuColor 12/DCCS50

Cleaning Systems

Reissue

Principles of Operation

– Photoreceptor Scraping Blade

– Flicker Bar

– Bead Pick-off Roll (BPO)

– Pre-Clean Corotron

– Photoreceptor Waste Auger

• IBT cleaning components -

– IBT Scraping Blade (cammed)

–IBT Waste Auger

– Film Blade (thin Mylar seal)

The Toner Recovery Auger rotation is monitored by an Auger Sensor. A semi-circle flag

at

ta

ched to the end of the Auger rotates through the Sensor as the Auger rotates. The Sensor

is sampled 10 times (0.1 sec. cycle) every 2 seconds while the Drum Motor rotates. An Auger

“caution” (09-424) is indicated at the User Interface when the Sensor does not detect move-

ment (high/low status of rotating flag) 4 times continuously.

An Auger Broken “fail” status (09-358) is indicat

ed when t

he number of copies reaches a spec-

ified value after the “caution” status is activated and remains.

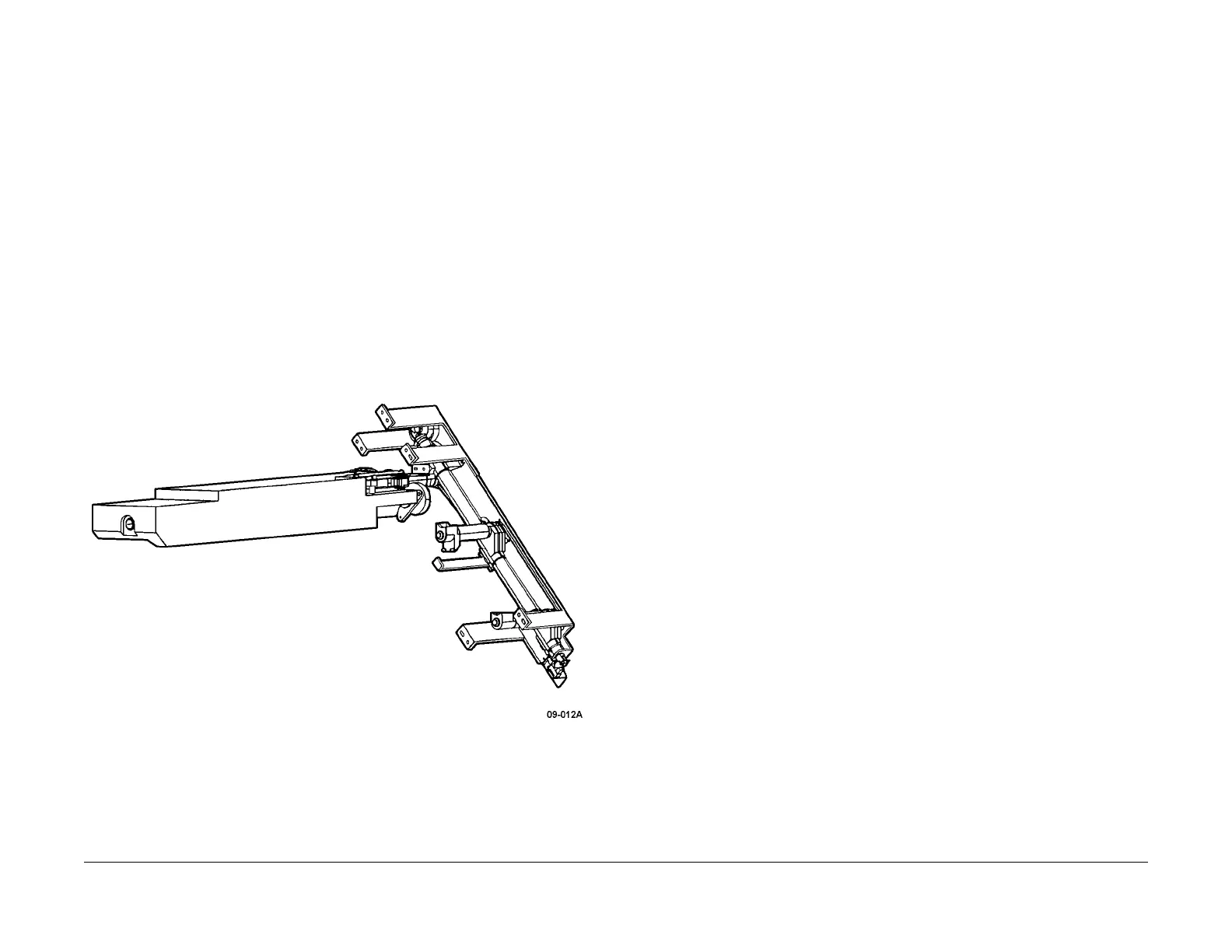

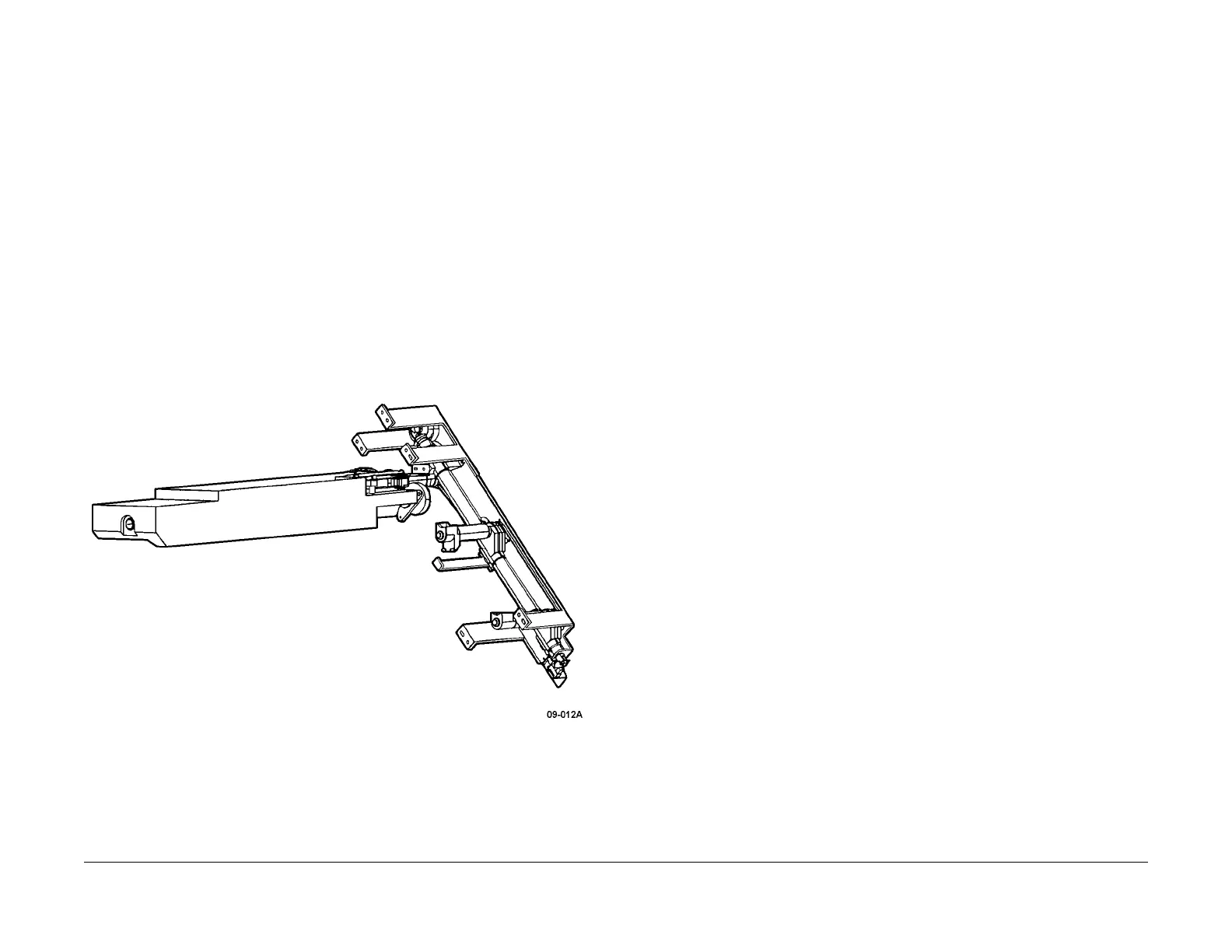

Figure 2 Junction Assembly for Waste Toner Disposal

Figure 3 shows p

art of the Waste Toner Auger Junction Assembly which is located in the back

of the machine. This system uses separate jointed augers to acquire waste toner from the Pho-

toreceptor Drum and the IBT. These augers transpor

t t

he waste toner the Slanting Auger,

which transports the toner to the Bottle Auger. The Bottle Auger transports the waste toner into

Waste Toner Bottle.

The Waste Toner Bottle is a CRU with the capacity to hold 2600cc of toner residue with full vol-

ume at 80% (expected bottle life to full at 40Kpv). As shown in Fi

gu

re 1, two augers are used to

fill the bottle:

• Bottle Auger - This feeds the waste toner into the bot

tle and is a part of the Auger Junction

Assembly.

• Coil Auger - This is inside the bottle and is part of it. It helps distribute and pack the waste

toner wit

hin the bottle.

The Main Motor drives the jointed augers, the Slanting A

uger the Bottle Auger and the Coil

Auger. This motor is energized at the start of a copying or printing job.

The Waste Toner Sensor is a photoelectric s

ensor that checks for the presence of the Waste

Toner Bottle. This is done when the machine is powered on and the Front Interlock Switch is

closed. A No Waste Bottle failure (09-374) is indicated when the sensor does not see the Bot-

tle.

The Waste Toner Bottle Full Sensor is monitored 3 times a second while the Drum Motor

rot

at

es. When the sensor detects a full status continuously for 3 seconds, then a near full “cau-

tion” (09-420) is indicated at the User Interface.

After the “caution” status, the machine counter monitors and compares to an NVM value the

f

ollowing

cycles to determine a Waste Bottle Full status“fail” (09-376):

• Toner Dispense Motor run time

• Number of copies

The “near full” and “full” status for the Waste Toner Bot

tle is reset by using the same bottle

sampling method, and the bottle is sensed empty 2 or more times per second.

manuals4you.commanuals4you.com

Loading...

Loading...