1/05

3-17

DocuColor 12/DCCS50

IQ 12 Bands, Lines, Smears, or Streaks RAP

Image Quality

Reissue

YN

Replace the Cleaner Assembly (PL 7.

1)

Check the IBT Belt for scratches lines or band. The IBT Belt is good.

YN

Replace the IBT Belt (PL 7.5).

Choose IOT Test Pattern #11 from the UI, or Test Pattern # 99 from the PWS, and make a

black, ye

llow, magenta, and cyan print of the test pattern. The defect appears in all four col-

ors.

YN

Replace the Developer for the problem color (PL

6.

6). If the problem continues, replace

the Developer Housing (PL 6.6).

• Check the photoreceptor, the corotron wire, and the corot

ron grid for defects or damage. If

any component is questionable, replace the Drum CRU (Machine Consumables).

• Check the Erase Lamp for dark spots. If the lamp is questi

onable, Replace the Erase

Lamp (PL 5.1).

• Clean the ROS of obstructions or contamination. If

the problem continues, replace the

ROS (PL 4.1).

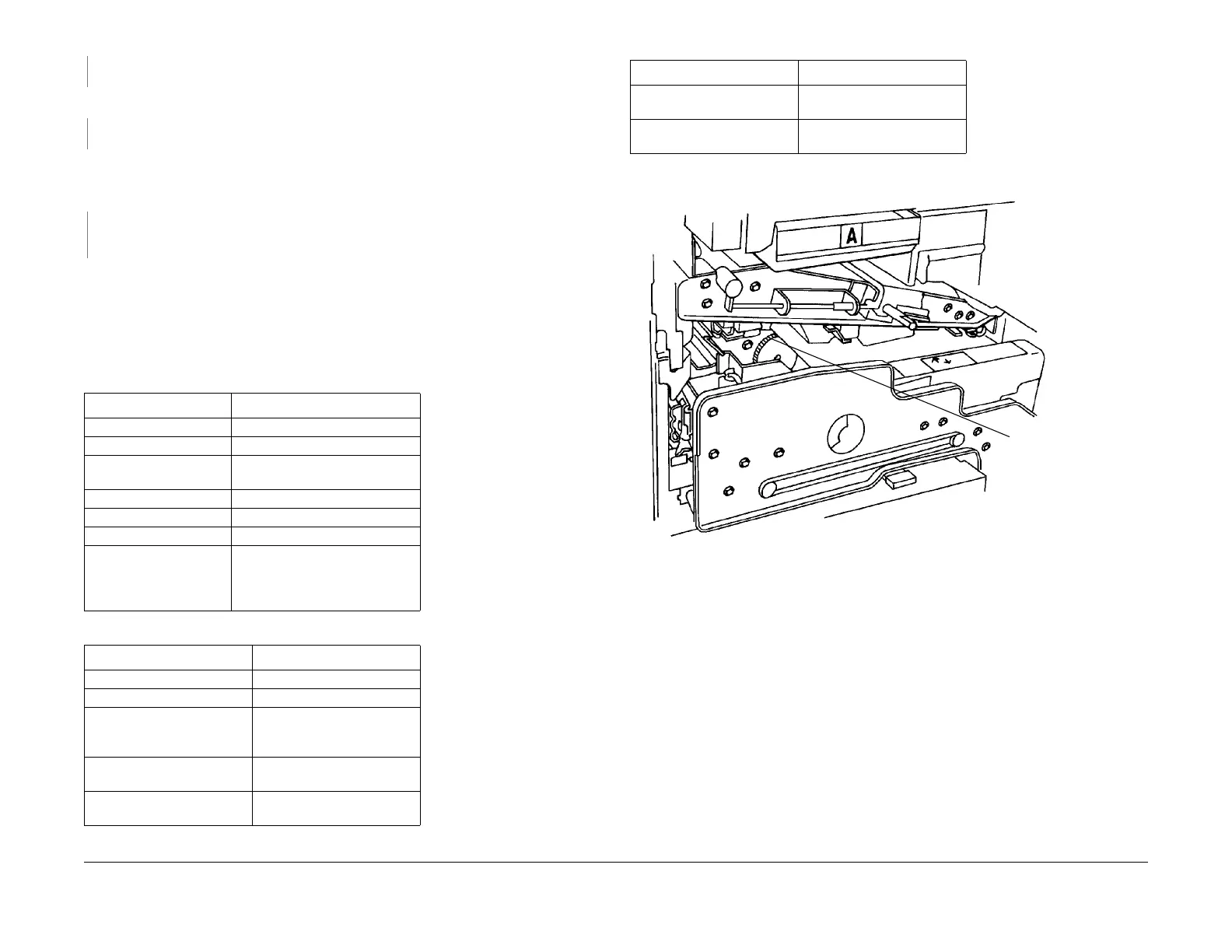

Figure 1 Registration Drive Gear

Table 1 Banding Intervals and Causes

Banding Interval in mm Component

0.51 ROS

1.02 ROS

6.6 Drum Motor (PL

1.

1), Main Motor

(PL 1.2)

39.14 Gears associated with Mag Roll

40.84 Gears associated with Mag Roll

52.78 Gears associated with IBT Roll

105.77 IBT Drive Assy which includes

double-gear 22/64T

(PL 1.1),

Drum Idler Gear (PL 1.1), and

IBT Drive Roll (PL 7.6)

Table 2 Checks For Other Banding Causes.

Problem to check for Corrective Action

Dirty Drum Gear Clean the Drum Gear

Loose Drum Flange Tighten Drum Flange

Dirty Corotron Wire/Corotron

Gr

id

Cl

ean with brush or replace

Drum CRU Machine Con-

sumables

Streak on IBT Hard stop to verify. Change

IB

T B

elt if defective

Streak on back side of copy. Check 2nd BTR Roll for dam-

age or contamination

White deletion streak from

lead edge to trail edge

Check for trimmer gap block-

age on developer mag rolls.

Poor Developer Bias Contact Clean/Replace the Bias

Brush (PL 6

.1)

Table 2 Checks For Other Banding Causes.

Probl

em to check for Corrective Action

Registration

Drive Gear

Loading...

Loading...