1/05

6-21

DocuColor 12/DCCS50

General Procedures

Reissue

132 Set Machine Serial Number.

Read Billing Meter Information

If you have replaced the PWB that

has a Machine Serial Number, check

the PWB and set the Machine Serial

Number.

Reads Billing Meter Information for

t

he fo

llowing:

•IOT CPU PWB

• Half-Tone PWB

•IOT NVM PWB

135 Service Data

HFSI Counter

Displays the regular part replacement

life

expectancy (threshold) and cur-

rent value (usage). You can change

t

he replacem

ent life expectancy to a

preset value in the PWS database

and reset the current value.

140 Component Check: Analog Monitor Monitor the analog values of the sen-

sors (A/D conversion) while operating

t

he comp

onents (e.g., C.C). You can

temporarily change the output value.

188 Service Mode Exit Screen Displays the requirements for exit

f

ro

m the Service Mode.

301 NVM access: NVM initialization Commands NVM Data initialization

for

initialization of:

•IISS

• Post IPS

•IOT

•SYS

•UI

305 System Test: Component Operation

Check UI

Component Check

Checks the UI Screen and Compo-

nent Panel Button operation.

330 Component Check: Component Con-

trol

Displays the instructions and results

of the

Input Component Check and

Output Component Check

1. You can monitor each Input

Comp

onent or check

the opera-

tion of each Output Component.

2. You can simultaneously check

mult

ip

le Input Components and

Output Components up to 11

total.

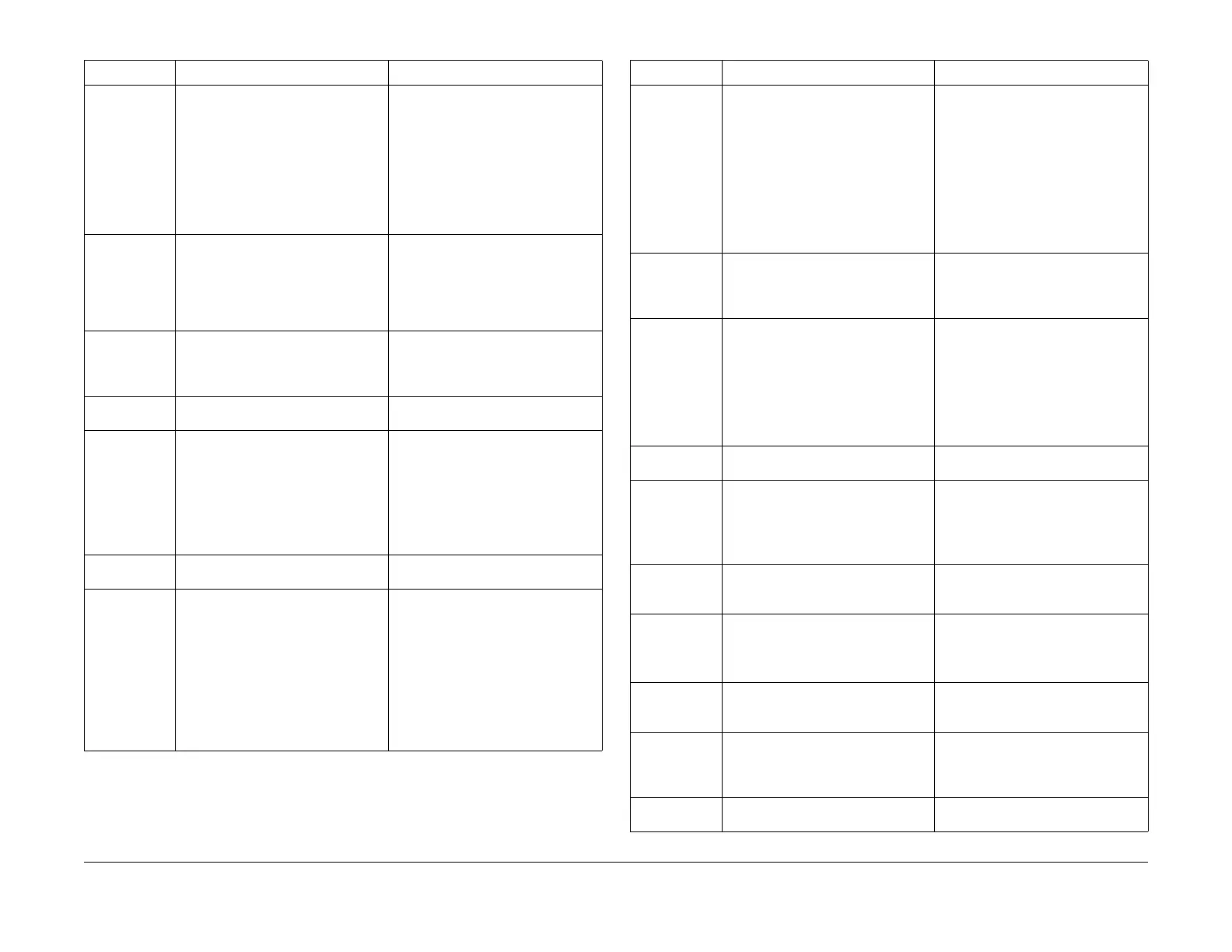

Table 1 dC Routines

d

C Nu

mber Name Description

351 NVM Background Processing 1. Saves and restores values of all

NVM in PWS dC131 databank.

NOTE: Background Read must

compl

ete prior to saving.

2. Start and Stop background NVM

Read.

3. Sav

es/restores machine set-

tings. Saves NVM values listed:

4. Resets all HFSI.

361 NVM access: Save/Restore NVM Saves the machine NVM data in the

PWS.

Restores the machine NVM

data (stored in the PWS) back to the

machine.

371 Configuration Page Allows viewing of current software

vers

ion and Mar

ket Place setting,

Machine Configuration, Output

Device(s), Accessories, Tray 1 Paper

Size setting, Feature Config., and

Input Device.

These settings can be changed to

align wit

h the m

achine configuration.

391 Edit Pad Can change the Edit Pad custom

color(s).

612 Color Tes

t Pattern Print 1. Outputs a test pattern to identify

a copy quali

ty problem.

2. Generates a test pattern from

the

Pattern Generator in the

machine.

701 Other Adjust/Set: Fuser Nip Measure-

ment

Make a copy for a contact arc adjust-

ment and measure the fuser nip width

by

a si

mple operation.

740 Tray 5 (Bypass) guide adjustment 1. Re-calibrate Size Sensor

2. Check if the Tray 5 guide size in

the

width direction has been

properly detected.

915 Machine data output: XERO data dis-

play

Displays the machine Xerographic

dat

a in t

he PWS in a format that is

easy to see and understand.

918 IOT Highlight Setup Uniform the Highlight Density Repro-

duction Starting Point (for each K, Y,

M,

C)

and the Highlight Density of In/

Out.

919 Color Balance Setup

(IIT machine only)

Make a 4C copy in the Photo mode.

Adjus

t t

he YMCK color balance.

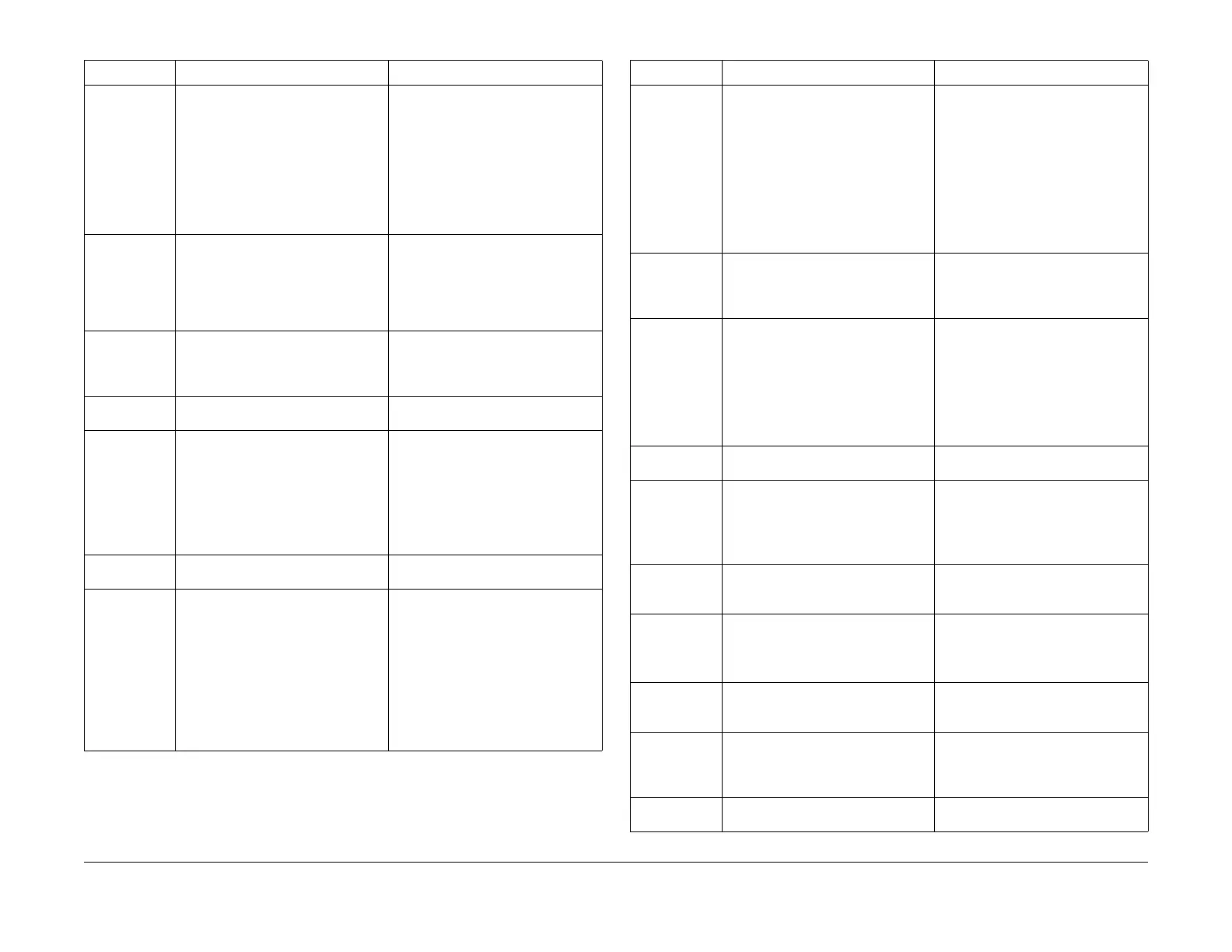

Table 1 dC Routines

d

C Numb

er Name Description

Loading...

Loading...