RM0046 FlexPWM

Doc ID 16912 Rev 5 677/936

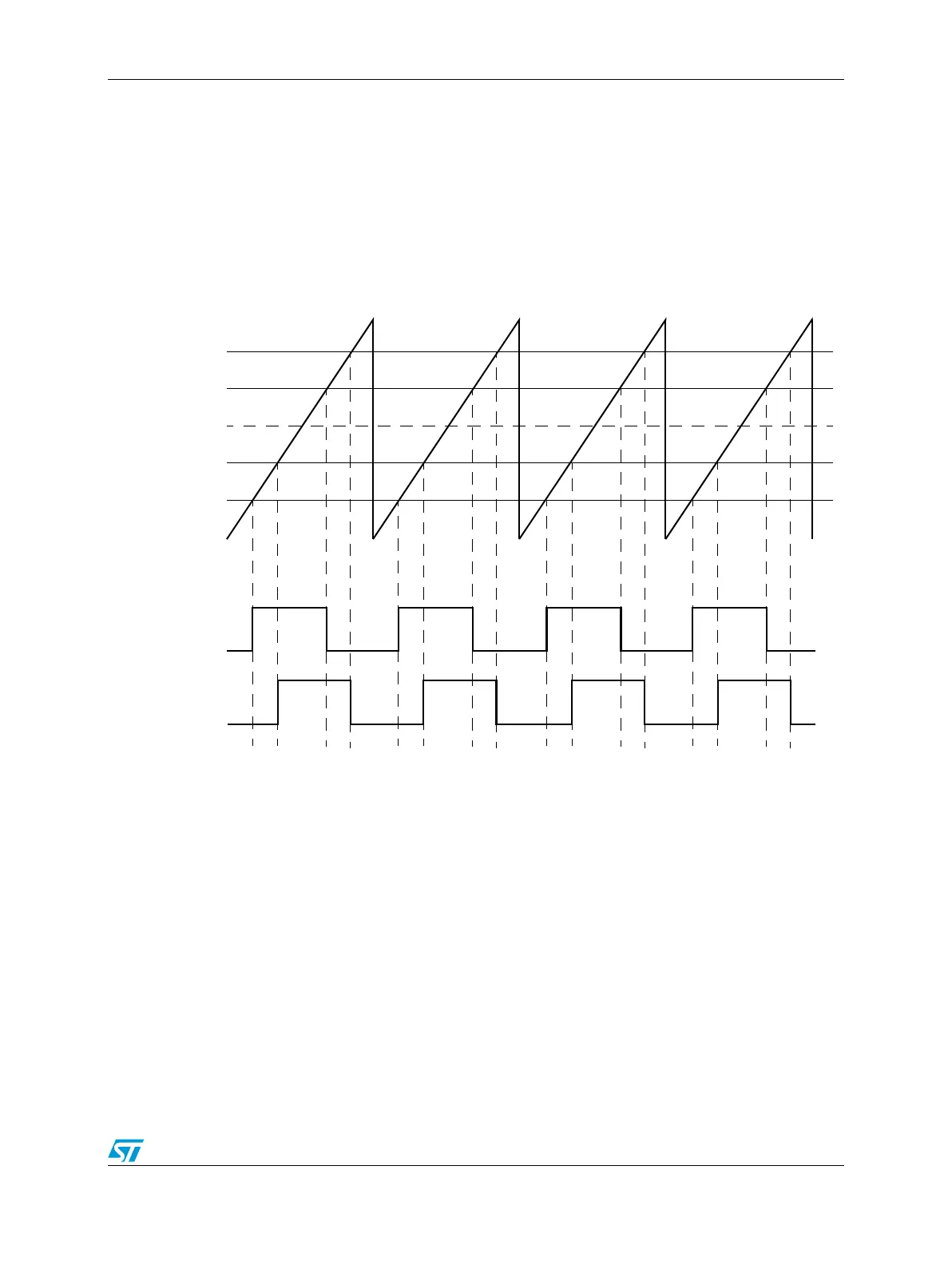

are applied to the turn on and turn off edges of different PWM signal, the signals will be

phase shifted with respect to each other, as illustrated in Figure 363. This results in certain

advantages when applied to a power stage. For example, when operating a multi-phase

inverter at a low modulation index, all of the PWM switching edges from the different phases

occur at nearly the same time. This can be troublesome from a noise standpoint, especially

if ADC readings of the inverter must be scheduled near those times. Phase shifting the

PWM signals can open up timing windows between the switching edges to allow a signal to

be sampled by the ADC. However, phase shifting does not affect the duty cycle so average

load voltage is not affected.

Figure 363. Phase-shifted outputs example

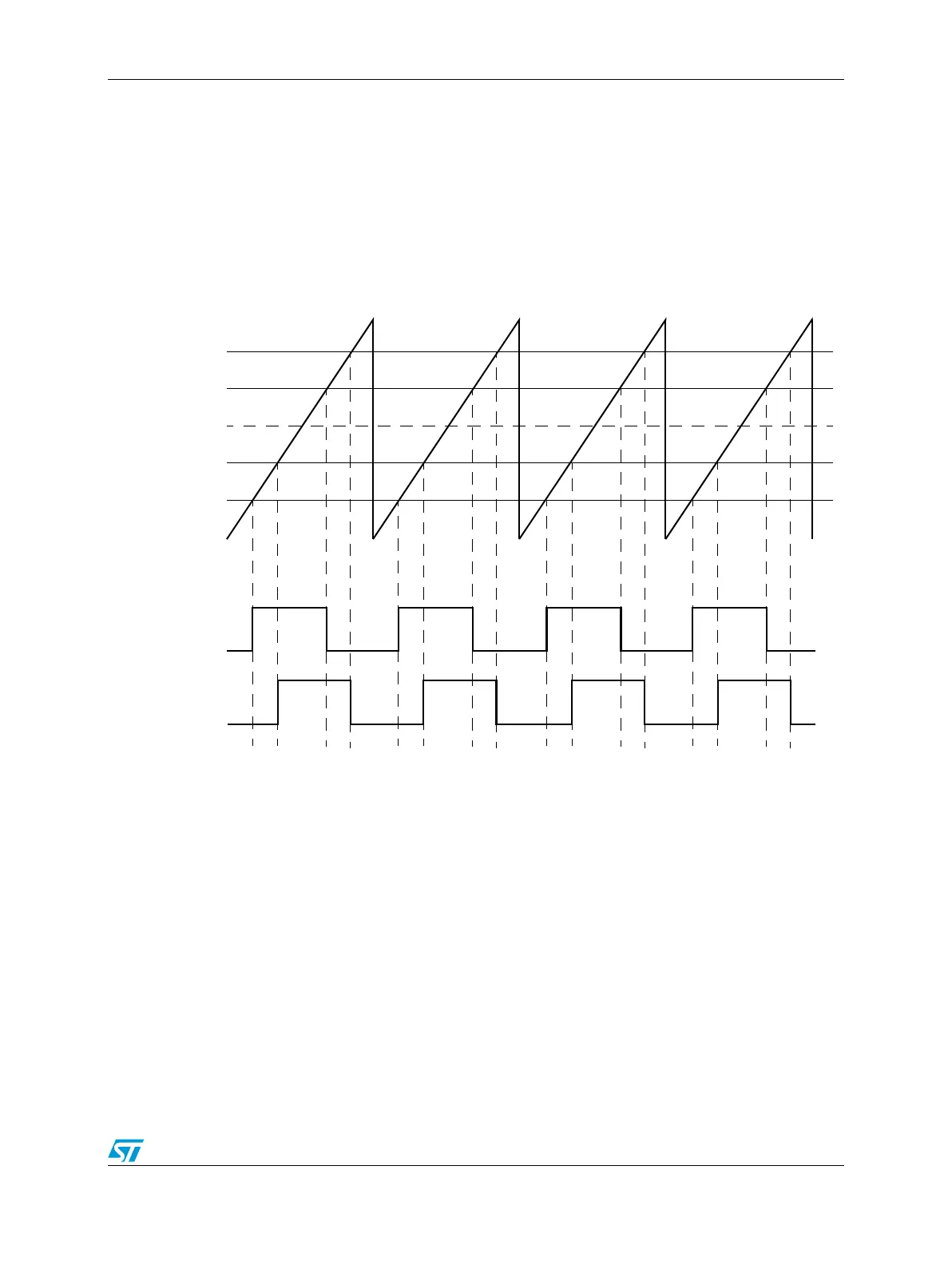

An additional benefit of phase-shifted PWMs can be seen in Figure 364. In this case, an H-

bridge circuit is driven by four PWM signals to control the voltage waveform on the primary

of a transformer. Both left and right side PWMs are configured to always generate a square

wave with 50% duty cycle. This works for the H-bridge since no narrow pulse widths are

generated, reducing the high-frequency switching requirements of the transistors. Notice

that the square wave on the right side of the H-Bridge is phase-shifted compared to the left

side of the H-Bridge. As a result, the transformer primary sees the bottom waveform across

its terminals. The RMS value of this waveform is directly controlled by the amount of phase

shift of the square waves. Regardless of the phase shift, no DC component appears in the

load voltage as long as the duty cycle of each square wave remains at 50%, making this

technique ideally suited for transformer loads. As a result, this topology is frequently used in

industrial welders to adjust the amount of energy delivered to the weld arc.

VAL1 (0x0100)

VAL5

VAL3

VAL0 (0x0000)

VAL4

VAL2

INIT (0xFF00)

PWMA

PWMB

Loading...

Loading...