FlexPWM RM0046

692/936 Doc ID 16912 Rev 5

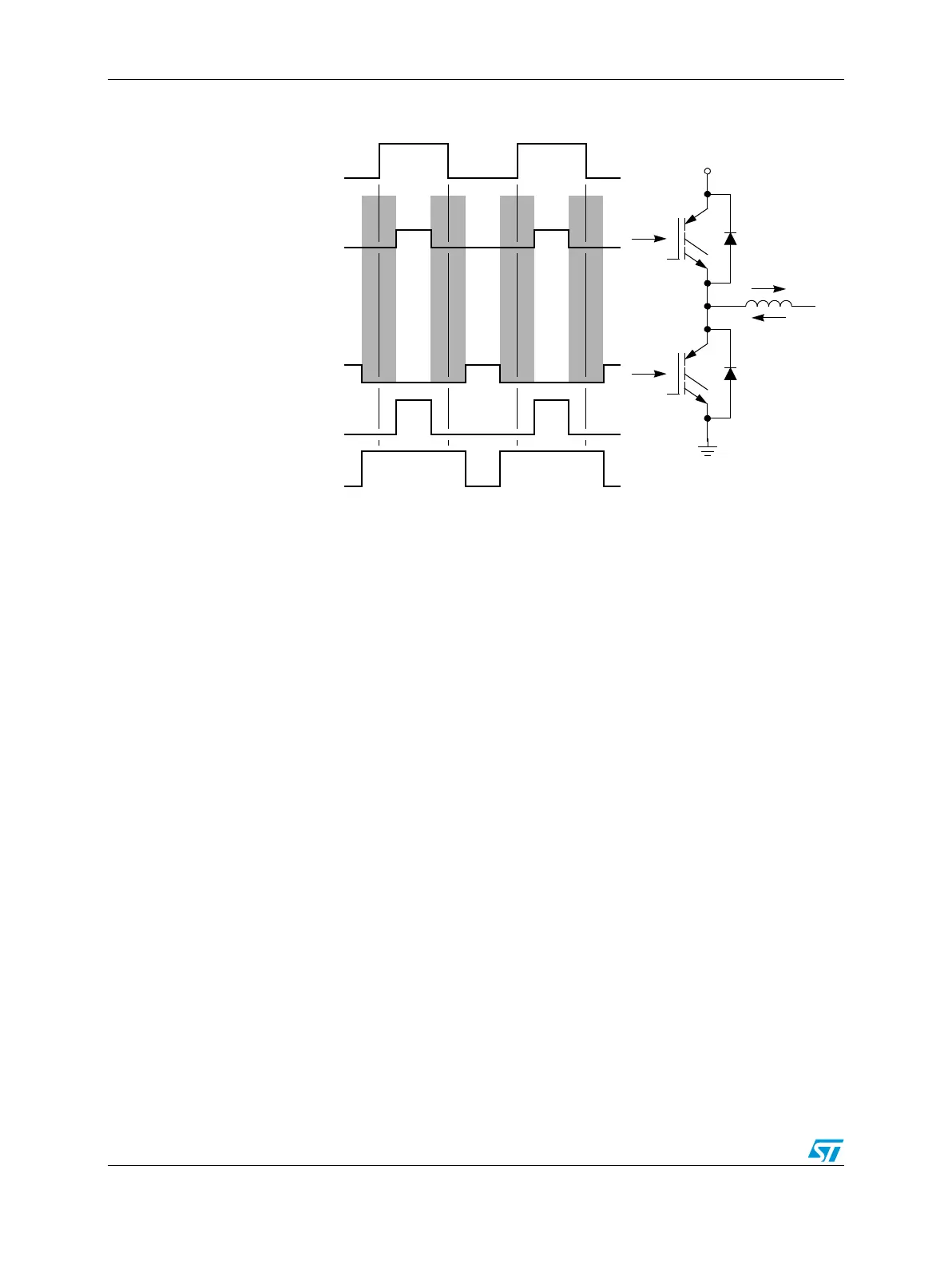

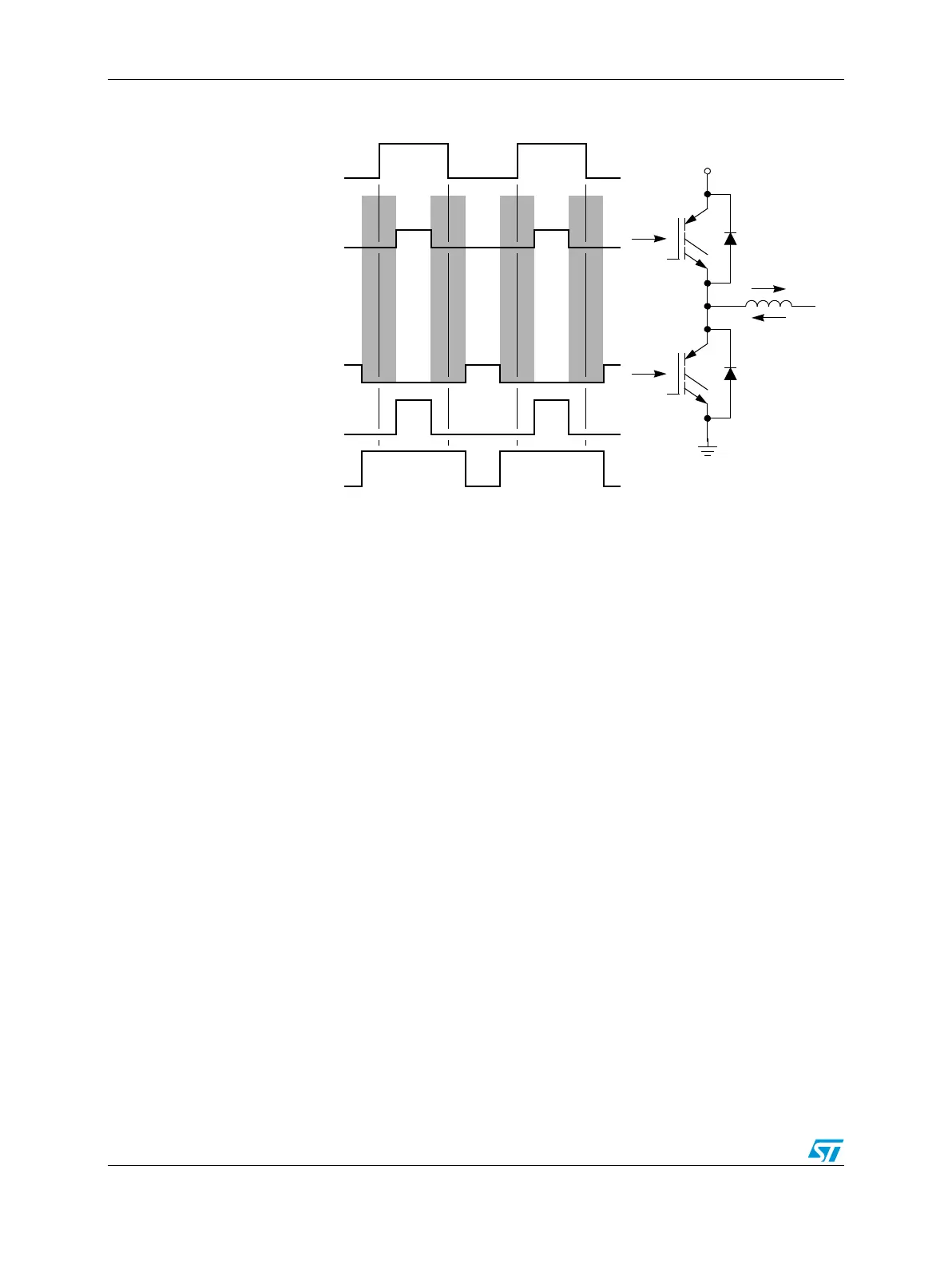

Figure 378. Deadtime distortion

During deadtime, load inductance distorts output voltage by keeping current flowing through

the diodes. This deadtime current flow creates a load voltage that varies with current

direction. With a positive current flow, the load voltage during deadtime is equal to the

bottom supply, putting the top transistor in control. With a negative current flow, the load

voltage during deadtime is equal to the top supply putting the bottom transistor in control.

Remembering that the original PWM pulse widths where shortened by deadtime insertion,

the averaged sinusoidal output will be less than the desired value. However, when deadtime

is inserted, it creates a distortion in the motor current waveform. This distortion is

aggravated by dissimilar turn-on and turn-off delays of each of the transistors. By giving the

PWM module information on which transistor is controlling at a given time this distortion can

be corrected.

For a typical circuit in complementary channel operation, only one of the transistors will be

effective in controlling the output voltage at any given time. This depends on the direction of

the motor current for that pair. See Figure 379. To correct distortion one of two different

factors must be added to the desired PWM value, depending on whether the top or bottom

transistor is controlling the output voltage. Therefore, the software is responsible for

calculating both compensated PWM values prior to placing them in the VALx registers.

Either the VAL2/VAL3 or the VAL4/VAL5 register pair controls the pulse width at any given

time. For a given PWM pair, whether the VAL2/VAL3 or VAL4/VAL5 pair is active depends on

either:

● The state of the current status pin, PWMx, for that driver

● The state of the odd/even correction bit, IPOL, for that driver

Desired

Deadtime

PWM to top

Positive

Negative

PWM to bottom

Positive current

Negative current

load voltage

transistor

transistor

load voltage

load voltage

current

current

V+

Loading...

Loading...