FlexPWM RM0046

690/936 Doc ID 16912 Rev 5

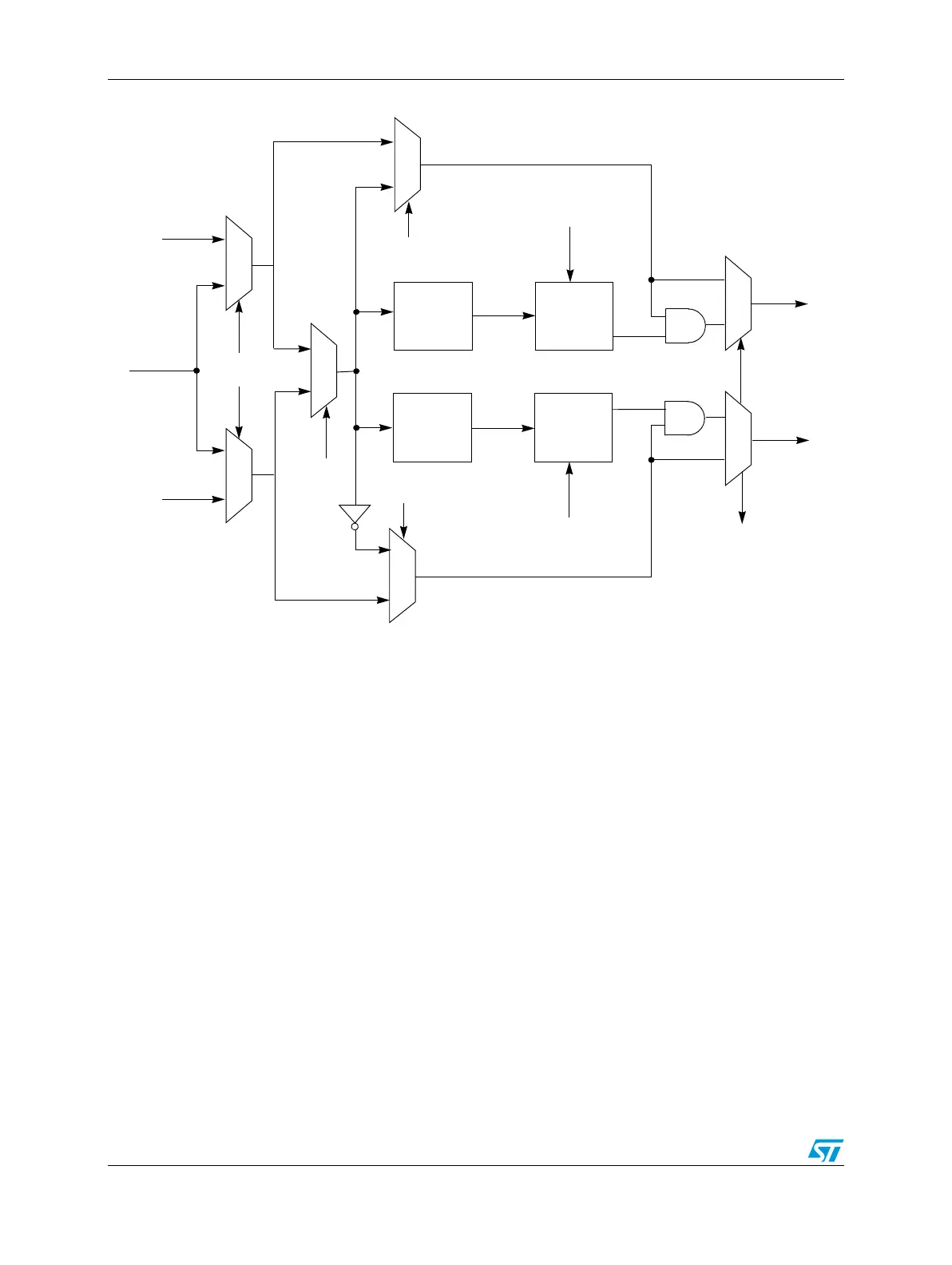

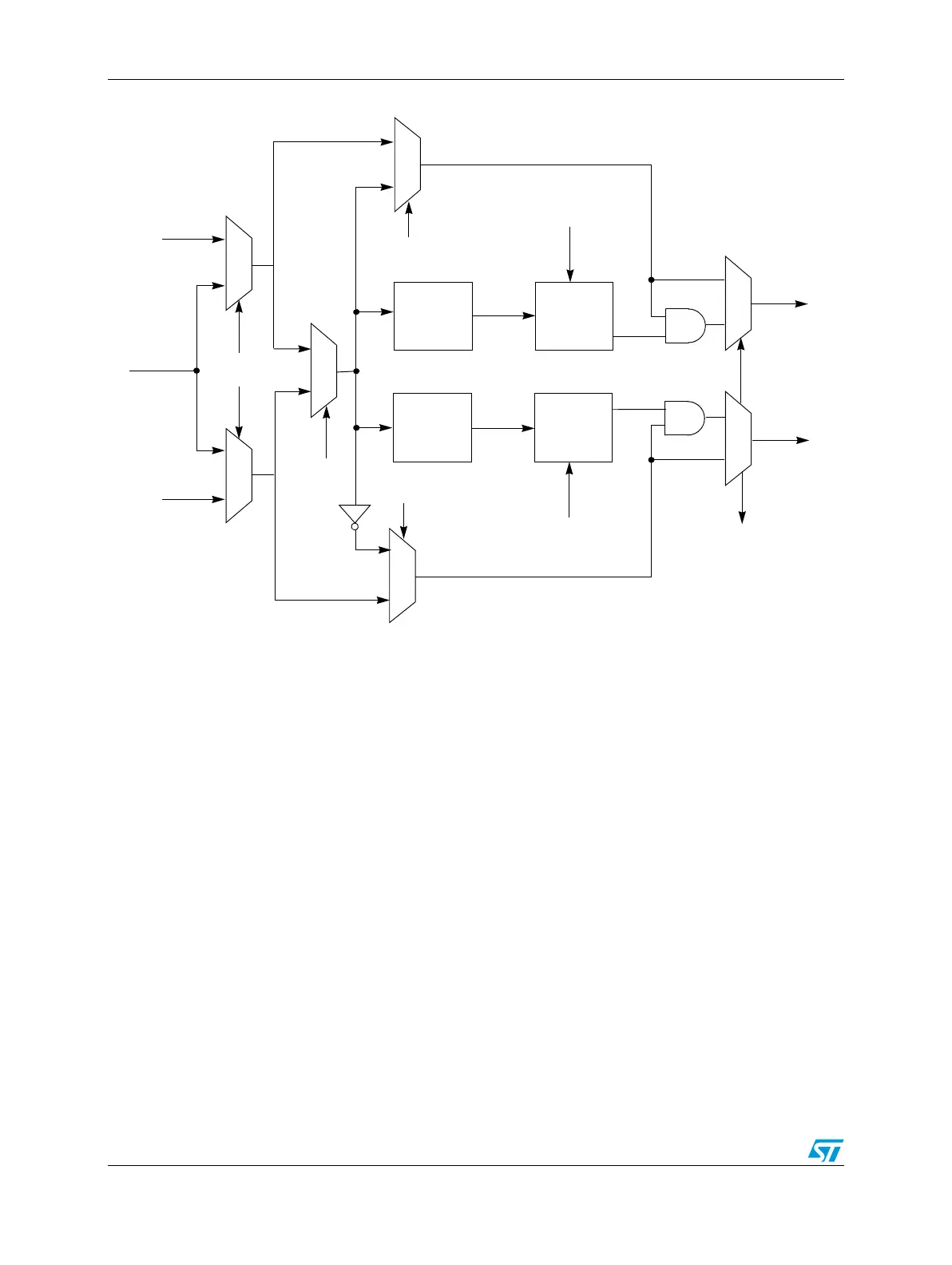

Figure 376. Deadtime insertion and fine control logic

While in the complementary mode, a PWM pair can be used to drive top/bottom transistors,

as shown in Figure 376. When the top PWM channel is active, the bottom PWM channel is

inactive, and vice versa.

Note: To avoid short-circuiting the DC bus and endangering the transistor, there must be no

overlap of conducting intervals between top and bottom transistor. However, the transistor’s

characteristics may cause its switching-off time to be longer than its switching-on time. To

avoid the conducting overlap of top and bottom transistors, deadtime needs to be inserted in

the switching period, as illustrated in Figure 377.

The deadtime generators automatically insert software-selectable activation delays into the

pair of PWM outputs. The deadtime registers (DTCNT0 and DTCNT1) specify the number of

IPBus clock cycles to use for deadtime delay. Every time the deadtime generator inputs

change state, deadtime is inserted. Deadtime forces both PWM outputs in the pair to the

inactive state.

When deadtime is inserted in complementary PWM signals connected to an inverter driving

an inductive load, the PWM waveform on the inverter output will have a different duty cycle

than what appears on the output pins of the PWM module. This results in a distortion in the

voltage applied to the load. A method of correcting this, adding to or subtracting from the

PWM value used, is discussed next.

PWMA

from Force

Out logic

PWMA

rising

edge

detect

down

counter

start

DTCNT0

zero

PWMB

detect

edge

falling

counter

down

start

DTCNT1

zero

to Output

logic

0

1

IPOL

1

0

INDEP

0

1

0

1

INDEP

0

1

INDEP

0

1

DBLEN

PWMB

0

1

DBLPWM

Loading...

Loading...